In today’s competitive market, finding the right packaging machine manufacturer in Pune is crucial for businesses looking to streamline their operations and enhance product presentation. Pune, a hub for industrial innovation, has become a hotspot for companies specializing in packaging solutions. From pouch packing machines to automatic packaging machines, the city offers a wide range of options to meet diverse industry needs.

This guide aims to provide valuable insights into selecting the best packaging machine manufacturer in Pune. It covers essential aspects such as understanding packaging requirements, exploring popular machine types, and evaluating key features. The article also delves into customization options, cost analysis, and the importance of after-sales support. By the end, readers will have a comprehensive understanding of how to choose a packaging machine that aligns with their specific business needs and budget constraints.

Understanding Packaging Machine Requirements

When selecting a packaging machine manufacturer in Pune, it is crucial to assess production needs, identify target markets, and ensure regulatory compliance. These factors play a significant role in determining the most suitable packaging solution for a business.

Assessing Your Production Needs

To choose the right packaging machine, businesses must carefully evaluate their production requirements. This involves considering factors such as the types of products being packaged, the desired output rate, and the available space for equipment installation. Packaging machinery manufacturers in Pune offer a wide range of options, from pouch packing machines to automatic packaging machines, catering to various industries and production scales.

For instance, food packaging machine manufacturers provide specialized equipment like snacks packaging machines and spice packaging machines. These machines are designed to handle specific product types and packaging formats, ensuring efficient and hygienic packaging processes. Similarly, manufacturers of vertical packaging machines and form fill seal machines offer solutions for businesses requiring versatile packaging options.

When assessing production needs, it is essential to consider factors such as:

- Product characteristics (e.g., liquid, solid, powdered)

- Packaging materials and requirements

- Desired pack shapes and dimensions

- Required output rate and accuracy

- Frequency and type of changeovers needed

By thoroughly evaluating these aspects, businesses can identify the most suitable packaging machine manufacturer in Pune to meet their specific requirements.

Identifying Target Markets

Understanding target markets is crucial when selecting packaging machinery. Different markets may have varying packaging preferences, regulations, and distribution requirements. For example, a business targeting the pharmaceutical industry may require specialized equipment like auger filler machines or volumetric fillers to ensure precise dosing and compliance with strict regulations.

Packaging machine manufacturers in Pune offer a range of solutions to cater to diverse market needs. For instance, fully automatic packing machines and multi-head weighers are suitable for high-volume production in industries such as snack foods and confectionery. On the other hand, pneumatic packing machines may be more appropriate for businesses dealing with delicate or fragile products.

Regulatory Compliance

Ensuring regulatory compliance is a critical aspect of selecting packaging machinery. Different industries and target markets may have specific regulations governing packaging materials, labeling requirements, and product safety standards. Packaging machine manufacturers in Pune must be well-versed in these regulations to provide compliant solutions.

For example, food packaging machines must adhere to food safety regulations and hygiene standards. Similarly, pharmaceutical packaging equipment needs to meet stringent quality control and traceability requirements. When choosing a packaging machine manufacturer in Pune, businesses should consider their expertise in regulatory compliance and their ability to provide documentation and support for validation processes.

By carefully assessing production needs, identifying target markets, and ensuring regulatory compliance, businesses can make informed decisions when selecting a packaging machine manufacturer in Pune. This approach helps in choosing equipment that not only meets current requirements but also supports future growth and market expansion.

Popular Packaging Machine Types in Pune

Pune has established itself as a hub for packaging machine manufacturers, offering a wide range of solutions to meet diverse industry needs. Some of the most sought-after packaging machines in Pune include:

Form Fill Seal Machines

Form Fill Seal (FFS) machines are highly sophisticated packaging machines that feature computer interfaces and control networks. These machines form the package, fill it with the product, and seal it in one continuous process. Many companies prefer FFS systems due to their speed and versatility. There are two main types of FFS machines:

Vertical Form Fill Seal Machines

Vertical Form Fill Seal (VFFS) machines are flexible automated assembly-line systems widely used in the packaging industry for food and various other products. These machines construct plastic bags from a flat roll of film while simultaneously filling them with products and sealing them. VFFS machines can handle both solids and liquids, making them suitable for packaging a wide range of items, from nuts and cookies to powders and granules.

Horizontal Form Fill Seal Machines

Horizontal Form Fill Seal (HFFS) machines are commonly used for packaging solid items that do not flow easily. These machines are designed with two molding stations and two sealing stations, allowing for automatic changeovers between different pack sizes without downtime. HFFS machines are preferred when packaging fragile products or when stand-up pouches with zippers or spouts are required.

Chips Packing Machine

Chips packing machines are in high demand in Pune, catering to the snack food industry. These machines are designed to handle delicate products like potato chips, ensuring efficient packaging without damaging the product. Many packaging machine manufacturers in Pune offer automatic chips packing machines with features such as multi-head weighers for accurate filling and nitrogen flushing to extend product shelf life.

Masala Packing Machine

Spice packaging is a significant industry in Pune, and masala packing machines are essential for this sector. These machines are designed to handle powders and granules efficiently, often incorporating auger fillers for precise dosing. Packaging machine manufacturers in Pune offer a range of masala packing machines, from semi-automatic to fully automatic systems, catering to various production capacities.

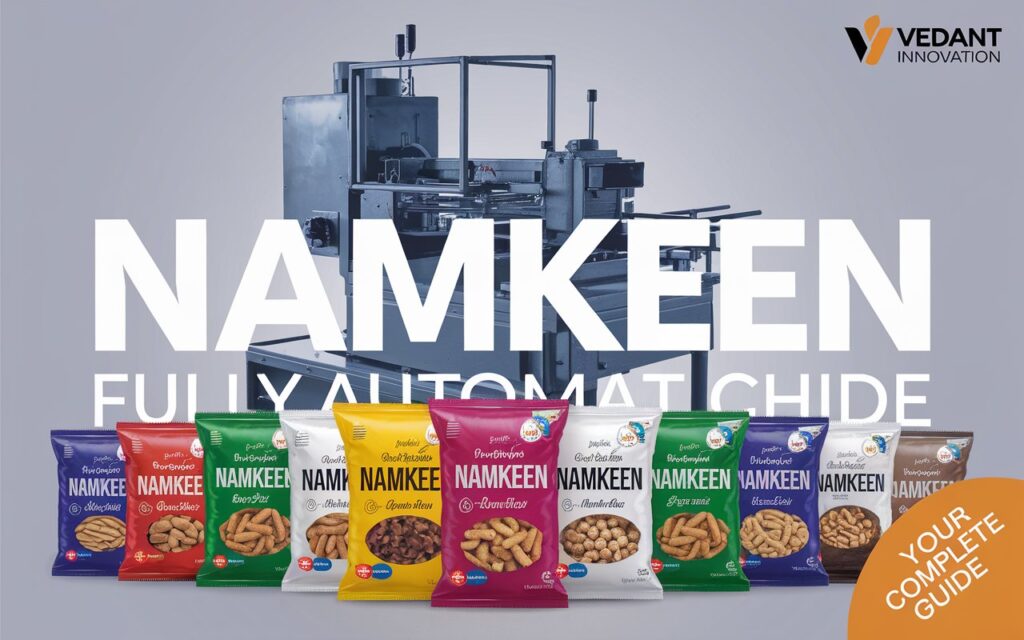

Namkeen Packing Machine

Namkeen, a popular Indian snack, requires specialized packaging machines. Namkeen packing machines in Pune are designed to handle a variety of snack shapes and sizes, often incorporating multi-head weighers for accurate filling. These machines can produce different pouch styles, including pillow packs and stand-up pouches, to meet diverse market demands.

Small Packing Machine

Small packing machines are popular among startups and small-scale industries in Pune. These compact machines offer versatility and cost-effectiveness, making them ideal for businesses with limited space or production requirements. Packaging machine manufacturers in Pune provide a range of small packing machines, including semi-automatic and automatic options, for various products such as grains, pulses, and small consumer goods.

Milk Packing Machine

The dairy industry in Pune relies heavily on efficient milk packing machines. These machines are designed to handle liquid products and maintain hygiene standards. Milk packing machines in Pune range from small-scale units for local dairies to high-capacity systems for large milk processing plants. Many of these machines incorporate features like UV sterilization and date coding to ensure product safety and traceability.

Key Features of High-Quality Packaging Machines

When selecting a packaging machine manufacturer in Pune, it’s crucial to consider the key features that distinguish high-quality equipment. These features contribute to the overall efficiency, reliability, and performance of packaging operations.

Precision and Accuracy

High-quality packaging machines excel in precision and accuracy, ensuring consistent product quality. Manufacturers in Pune incorporate advanced control systems and sensors to maintain exact specifications throughout the packaging process. This level of precision reduces waste and maximizes resource utilization, contributing to cost savings and environmental sustainability.

For instance, pouch packing machines and vertical packaging machines use sophisticated sensors and vision systems to ensure accurate label placement and product filling. These technologies enable real-time monitoring and adjustments, minimizing errors and enhancing overall accuracy.

Speed and Efficiency

Packaging machine manufacturers in Pune focus on developing equipment that optimizes production speed and improves process efficiency. Automated systems, such as fully automatic packing machines, allow businesses to achieve higher throughput rates and reduce labor costs dramatically. These machines can handle thousands of products in a fraction of the time it would take for manual labor, ensuring prompt response to market demands.

The integration of packaging machinery with other production line components creates a seamless workflow, further enhancing efficiency. This interconnected approach ensures that labels are applied in sync with other production stages, reducing downtime and boosting overall productivity.

Ease of Operation

User-friendly interfaces and intuitive controls are hallmarks of high-quality packaging machines. Manufacturers in Pune design equipment with simplified operation in mind, reducing the need for extensive operator training. For example, some machines feature visual scales and measurements, allowing for easy adjustments without tools or advanced technical knowledge.

Color-coded components and touch-screen interfaces make it simpler for operators to navigate machine functions and troubleshoot issues. This ease of operation contributes to reduced downtime and increased overall efficiency in packaging processes.

Durability

Packaging machine manufacturers in Pune prioritize durability in their equipment design. High-quality machines are built to withstand the rigors of continuous operation in industrial environments. Robust construction and the use of premium materials ensure longevity and reliability, reducing the frequency of repairs and replacements.

Regular maintenance is essential for maintaining the durability of packaging equipment. Manufacturers often provide comprehensive maintenance schedules and support to help businesses keep their machines in optimal condition. This proactive approach helps prevent breakdowns, ensures consistent performance, and extends the lifespan of the equipment.

By focusing on these key features, packaging machine manufacturers in Pune deliver solutions that meet the diverse needs of industries such as food, pharmaceuticals, and consumer goods. These high-quality machines contribute to improved productivity, reduced operational costs, and enhanced product quality, ultimately supporting businesses in their pursuit of excellence in packaging operations.

Customization Options for Packaging Machines

Packaging machine manufacturers in Pune offer a wide range of customization options to meet the specific needs of various industries. These customizations enable businesses to optimize their packaging processes and enhance overall efficiency.

Product-Specific Adaptations

Packaging machines can be tailored to handle specific product types, shapes, and sizes. For instance, snacks packaging machines can be modified to accommodate different snack formats, from chips to namkeen. Similarly, spice packaging machines can be adapted to handle various powder consistencies and granule sizes. These product-specific adaptations ensure that the packaging process is optimized for each unique item, resulting in improved efficiency and reduced waste.

Manufacturers in Pune also offer customization options for packaging materials. Pouch packing machines, for example, can be adjusted to work with different film types and thicknesses, allowing businesses to choose the most suitable packaging material for their products. This flexibility enables companies to adapt to changing market demands and consumer preferences.

Integrating with Existing Production Lines

One of the most significant customization options provided by packaging machine manufacturers in Pune is the ability to integrate new equipment with existing production lines. This integration ensures a seamless workflow and maximizes overall operational efficiency. For instance, a vertical packaging machine can be designed to fit perfectly into an existing production line, minimizing disruptions and reducing installation time.

Integration also extends to control systems and software. Many packaging machines can be customized to communicate with existing production management systems, allowing for real-time monitoring and data collection. This integration helps businesses maintain consistent quality control and optimize their entire production process.

Scalability for Future Growth

Packaging machine manufacturers in Pune understand the importance of scalability in today’s dynamic business environment. They offer customization options that allow for future expansion and upgrades. For example, a semi-automatic packaging machine can be designed with the capability to be upgraded to a fully automatic packing machine as production demands increase.

Scalability also applies to the range of products a machine can handle. Multi-head weighers and volumetric fillers can be customized to accommodate a broader range of product weights and volumes, allowing businesses to diversify their product lines without investing in entirely new equipment.

Furthermore, packaging machine manufacturers in Pune offer modular designs that allow for easy addition of new features or components. This modularity enables businesses to adapt to changing market requirements without replacing their entire packaging line.

By offering these customization options, packaging machine manufacturers in Pune provide businesses with the flexibility and adaptability needed to thrive in a competitive market. Whether it’s product-specific adaptations, seamless integration with existing systems, or scalability for future growth, these customization options ensure that businesses can find the perfect packaging solution to meet their unique needs and support their long-term success.

Cost Analysis and Return on Investment

When considering a packaging machine manufacturer in Pune, businesses must carefully evaluate the cost analysis and potential return on investment (ROI). This assessment helps companies make informed decisions about investing in automated packaging solutions.

Initial Investment vs Long-term Benefits

While the upfront cost of purchasing modern packaging machinery might seem substantial, the long-term benefits often outweigh the initial investment. Packaging machine manufacturers in Pune offer a range of options, from pouch packing machines to fully automatic packing machines, each with its own cost considerations. The efficiency gains, improved product quality, and minimized waste all contribute to a higher return on investment over time.

To calculate the ROI for a potential packaging machine purchase, businesses need to consider several factors:

- The total cost of ownership, including purchase price, freight costs, installation, training, and annual maintenance expenses.

- The estimated annual net benefit or loss generated by the new equipment.

- The payback period, which indicates how long it will take to recoup the initial investment.

For example, if a company invests in a ₹3,350,628 packaging machine that saves ₹2,094,143 annually in labor costs, the payback period would be approximately four years. This calculation helps businesses compare different machines and make informed decisions about their investments.

Energy Efficiency

Energy efficiency is a crucial factor in cost analysis and ROI calculations for packaging machines. Manufacturers in Pune are increasingly focusing on developing environmentally friendly solutions that consume less energy. These energy-efficient machines not only reduce operational costs but also help businesses achieve their sustainability goals.

When evaluating packaging machines, companies should consider:

- The machine’s energy consumption rates

- Potential energy savings compared to current packaging processes

- Long-term impact on utility costs

Investing in energy-efficient packaging solutions from reputable manufacturers in Pune can lead to significant cost savings over time, improving the overall ROI of the equipment.

Reduced Labor Costs

One of the most significant benefits of investing in automated packaging machines is the potential for reduced labor costs. Packaging machine manufacturers in Pune offer solutions that can dramatically decrease the need for manual labor in packaging operations.

By implementing automation, businesses can:

- Reduce the number of employees required to operate packaging lines, often by up to 50%

- Reassign staff to more productive, value-adding roles within the company

- Minimize costs associated with training, employee benefits, and potential workplace injuries

For instance, a snacks packaging machine or a namkeen packing machine can handle tasks that previously required multiple workers, allowing businesses to optimize their workforce and reduce labor expenses. This reduction in labor costs contributes significantly to the overall ROI of the packaging equipment.

In conclusion, while the initial investment in packaging machinery may seem substantial, the long-term benefits in terms of energy efficiency, reduced labor costs, and increased productivity often result in a favorable ROI. By carefully analyzing these factors and working with reputable packaging machine manufacturers in Pune, businesses can make informed decisions that support their growth and profitability in the long run.

Maintenance and After-Sales Support

Proper maintenance and reliable after-sales support are crucial factors to consider when selecting a packaging machine manufacturer in Pune. These aspects ensure the longevity and optimal performance of packaging equipment, ultimately contributing to the success of a business’s operations.

Preventive Maintenance Tips

Packaging machine manufacturers in Pune emphasize the importance of preventive maintenance to extend the life of equipment and minimize downtime. Regular inspections, routine servicing, and timely replacement of wear parts are essential components of a comprehensive maintenance program. Many manufacturers recommend developing a maintenance schedule that includes daily, weekly, monthly, and quarterly tasks.

For instance, operators should perform simple visual checks daily, while more in-depth maintenance activities may require the expertise of certified technicians. Some key preventive maintenance tips include:

- Regularly inspecting and cleaning machine components

- Lubricating moving parts as per the manufacturer’s guidelines

- Checking and adjusting belt tensions

- Monitoring and replacing wear parts before they fail

- Keeping high-wear parts in stock to minimize downtime

By adhering to these preventive maintenance practices, businesses can significantly reduce the risk of unexpected breakdowns and ensure consistent production quality.

Troubleshooting Common Issues

Despite regular maintenance, packaging machines may occasionally encounter issues. Packaging machine manufacturers in Pune often provide comprehensive troubleshooting guides to help operators address common problems quickly. These guides typically cover issues such as:

- Web breaks in pouch packing machines

- Poor web tracking in vertical packaging machines

- Sealing problems in form fill seal machines

- Cut-off issues in end sealers

For example, if a web break occurs in a pouch packaging machine, the operator might check for damaged rolls or misaligned transfer rolls. In case of poor seals, they might adjust sealer temperatures or pressure settings. By equipping operators with this knowledge, manufacturers help businesses minimize downtime and maintain productivity.

Availability of Spare Parts

The availability of spare parts has a significant impact on a packaging machine’s maintenance and overall performance. Reputable packaging machine manufacturers in Pune ensure a steady supply of spare parts for their equipment. They often provide customers with a recommended spare parts list, categorizing parts based on their wear rates and criticality.

For instance, high-wear parts such as sealing jaws or cutting blades should be kept in stock to avoid prolonged downtime. Medium-wear parts might have a longer lifecycle but may still require occasional replacement. Low-wear parts are less likely to fail but should still be available if needed.

Many manufacturers also offer online spare parts catalogs and quick shipping options to minimize downtime when replacements are required. This level of support ensures that businesses can maintain their packaging operations efficiently and cost-effectively.

By prioritizing maintenance and after-sales support, packaging machine manufacturers in Pune demonstrate their commitment to customer satisfaction and long-term partnerships. This approach not only helps businesses maintain their equipment but also contributes to improved productivity and reduced operational costs in the long run.

Conclusion

Choosing the right packaging machine manufacturer in Pune has a significant impact on a business’s efficiency, product quality, and bottom line. By carefully considering factors such as production needs, target markets, and regulatory compliance, companies can find equipment that aligns perfectly with their requirements. The wide range of customization options, from product-specific adaptations to scalability for future growth, allows businesses to tailor their packaging solutions to their unique needs.

Investing in high-quality packaging machinery often leads to long-term benefits that outweigh the initial costs. The potential for reduced labor expenses, improved energy efficiency, and increased productivity contributes to a favorable return on investment over time. To make the most of these benefits and ensure the longevity of their equipment, businesses should prioritize proper maintenance and after-sales support. For help in selecting the best packaging machine for your business, give us a call at 9920144792.

FAQs

What factors should I consider when selecting a packaging machine?

When choosing a packaging machine, consider these six essential factors:

- The speed of the packaging machinery to match production demands.

- Environmental friendliness of the machine.

- Overall costs associated with the packaging machine.

- The need for staff training on the new machinery.

- Flexibility and adaptability of the machine to different packaging needs.

- Warranty provided with the packaging machinery.