Introduction

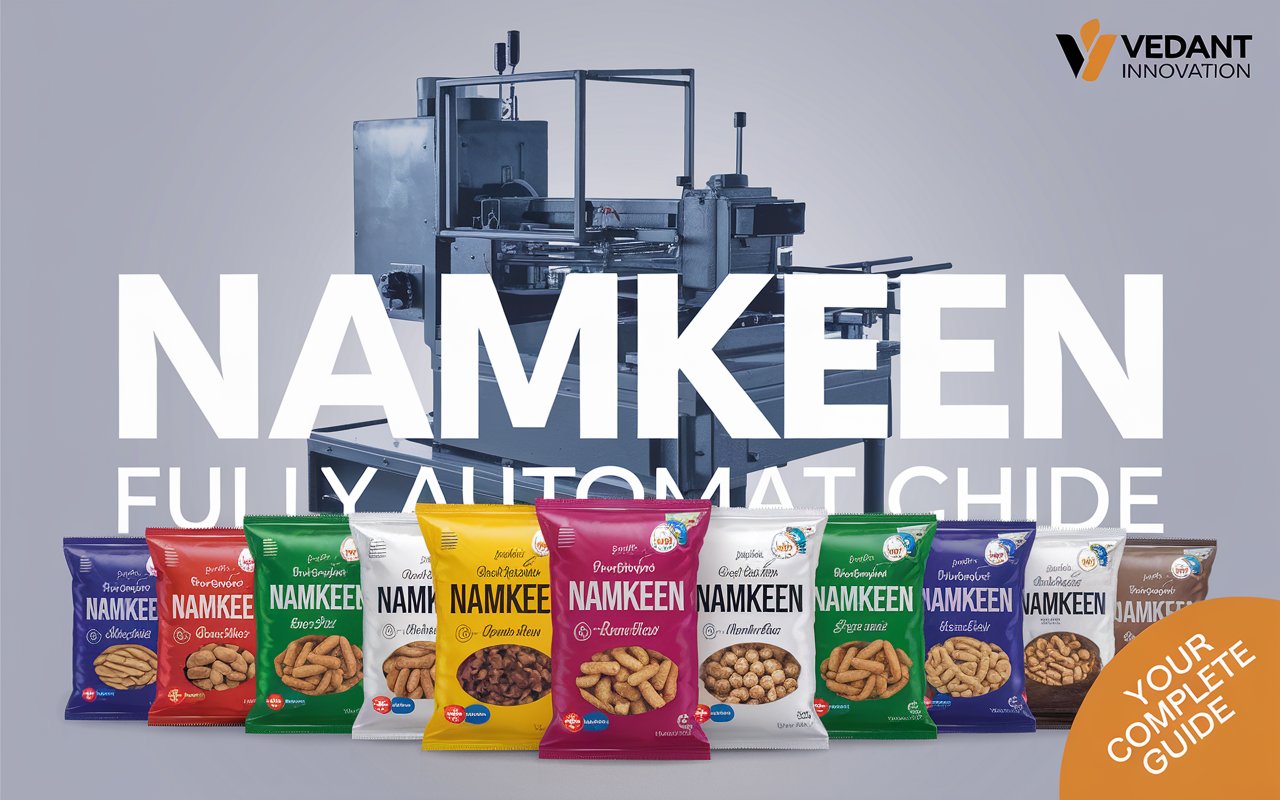

When it comes to snacks, namkeen holds a special place in many hearts, especially in India. With the rising demand for these savoury treats, the need for efficient packaging solutions has never been more important. In this post, we will explore the world of fully automatic namkeen packing machines, designed to handle varied weights, from 20 grams to 1 kilogram. We’ll delve into the types of machines available, their prices, and the factors to consider when making a purchase.

Overview of Namkeen Packing Machines

Namkeen packing machines have revolutionized the snack industry by automating the packaging process. These machines not only save time but also ensure consistency and hygiene in packaging. Automation in packing allows manufacturers to meet the increasing demand swiftly and productively, adapting to market trends with ease.

Importance of Automation in Packing

Automation brings numerous benefits, including enhanced efficiency, reduced labour costs, and improved product integrity. In the fast-paced snacks market, where consumer preferences shift rapidly, being able to pack namkeen quickly and neatly is essential for staying competitive.

Scope of the Article

This article will cover:

- The basics of namkeen and market demand.

- Types of fully automatic packing machines.

- Factors influencing their prices.

- Benefits of using these advanced machines.

- A buyer’s guide for selecting the right equipment.

1. Understanding Namkeen and Its Market Demand

1.1 What is Namkeen?

Namkeen refers to a range of savoury snacks very popular in Indian cuisine. They come in various forms, including:

- Chips: Thin slices that are fried or roasted.

- Nuts and Seeds: Often mixed with spices.

- Fried Snacks: Such as bhujia and kachori.

- Coated Snacks: Like masala peanuts or puffed rice.

Common ingredients include gram flour, spices, and sometimes nuts or dried fruits. The flavours can vary from spicy to tangy, tapping into the diverse tastes across different regions in India.

“Namkeen isn’t just food; it’s a comfort that brings back childhood memories for many!”

1.2 Market Trends for Namkeen

The snacks industry is growing rapidly. Factors contributing to this growth include:

- Increased Urbanization: With more people living in cities, there’s a higher demand for quick and tasty snacks.

- Changing Lifestyles: Busy schedules and on-the-go lifestyles drive consumers to seek convenient options.

- Rise of Health-Conscious Consumers: Many are now looking for healthier options, which manufacturers are starting to cater to by using organic ingredients or reducing oil content.

1.3 Consumer Preferences and Packaging Needs

Consumers are becoming more selective about their snacks, impacting packaging preferences.

- Importance of Packaging: Eye-catching designs can influence purchasing decisions.

- Environmental Concerns: Increasingly, individuals prefer sustainable packaging materials.

- Demand for Convenience: Single-serving packages are on the rise to cater to modern consumers’ busy lives.

2. Types of Fully Automatic Namkeen Packing Machines

2.1 Basic Features and Specifications

Most fully automatic namkeen packing machines come equipped with:

- Typical Size and Capacity Options: These machines can pack a variety of weights, ranging from small 20 grams to larger 1 kg packages.

- Basic Functionalities: They often include automatic filling, sealing, and labeling systems.

- Material Compatibility: Many machines can handle various packaging materials such as plastic, foil, or paper.

2.2 Variants Based on Weight Range

- Machines for Low-Weight Packings (20 gm – 200 gm): Good for single-serving snacks.

- Machines for Medium-Weight Packings (201 gm – 500 gm): Suitable for family-sized packs.

- Machines for High-Weight Packings (501 gm – 1 kg): Ideal for bulk buyers or large families.

2.3 Specialized Machines for Different Namkeen Types

- Machines for Dry Namkeen Suspensions: Designed specifically for dry snacks like plain chivda.

- Machines for Coated and Fried Namkeen: Tailored to handle more delicate items that require careful handling.

- Machines for Bulk and Bulk-Filling Applications: Capable of efficiently packaging larger quantities with less fuss.

3. Factors Influencing Prices of Namkeen Packing Machines

3.1 Brand and Manufacturer Variability

Prices can differ based on brand reputation. Well-known brands may cost more but often provide reliable quality and service.

- Comparison of Renowned Brands: Brands like PackTech and Sumeet offer trusted solutions, while emerging brands may provide competitive pricing.

- Impact of Brand Reputation on Pricing: A well-established brand usually comes with guarantees of durability and support.

3.2 Machine Specifications and Customization Options

The complexity of the machine plays a significant role in pricing.

- Standard Features Versus Custom Solutions: A basic model will be less expensive compared to a customized machine tailored for a specific functionality.

- Impact of Technological Integration on Cost: Machines with advanced technology generally carry a higher price tag.

3.3 Economic Influences and Market Conditions

- Raw Materials and Production Costs: Fluctuations in materials can affect machine prices.

- Changes in Local vs. Imported Machine Prices: Local manufacturing may offer cost advantages compared to imported equipment.

- Influence of Global Economy on Pricing Trends: Economic changes globally can impact pricing and supply chains.

4. Benefits of Using Fully Automatic Packing Machines

4.1 Efficiency and Time-Saving Factors

Using these machines can lead to:

- Quicker Production Times: Reduced manual labor speeds up the entire packing process.

- Consistency in Quality and Packaging: Automation ensures that each package is sealed and filled uniformly.

- Reduced Labor Costs: Fewer employees are needed once automation is in place.

4.2 Enhanced Product Integrity and Hygiene

Fully automatic machines enhance food safety by:

- Protection Against Contaminants: Sealed packaging keeps product contaminations at bay.

- Improved Shelf Life of Namkeen: Proper packaging means snacks stay fresh longer.

- Compliance with Health Regulations: Many machines are designed to meet industry standards for food safety.

4.3 Flexible Packaging Solutions

These machines can adapt to various market needs:

- Adaptability for Different Namkeen Products: Whether it’s a new flavor or a different style of namkeen, machines can often be adjusted.

- Ability to Handle Various Weight Specifications: Switching between weight classes is often seamless.

- Options for Packaging Design and Customization: Eye-catching designs can set brands apart on the shelf.

5. Choosing the Right Machine: A Buyer’s Guide

5.1 Identifying Business Needs

Before purchasing, consider:

- Assessing Production Volume Requirements: Estimate how much namkeen you’ll produce daily.

- Understanding Market Demands and Target Consumers: Tailor your machine choice to what your consumers prefer.

- Evaluating Budget Constraints: Ensure the machine fits well within your financial plan.

5.2 Key Considerations for Machine Selection

When selecting your packing machine, keep in mind:

- Durability and Maintenance Requirements: Investing in a reliable machine can save costs in the long run.

- Technical Support and Warranty Services: Look for brands that provide solid support after purchase.

- User-Friendly Features and Training Needs: Ensure the machine is easy to operate and that staff can be trained without hassle.

5.3 Long-term Investment versus Short-term Needs

Weighing the benefits of the machine is crucial.

- Understanding Return on Investment (ROI): Calculate how quickly the machine can pay for itself.

- Analyzing Maintenance Costs over Time: An inexpensive machine may lead to higher maintenance costs and should be factored in.

- Potential for Future Scaling and Upgrading: Consider whether the machine can grow with your business.

Conclusion

Investing in a fully automatic namkeen packing machine can elevate your business, streamline operations, and meet increasing market demands efficiently. By understanding market trends, machine types, and pricing factors, you’re well on your way to making an informed choice that suits your needs. Choose wisely to set your business up for success!

FAQs

What is the average price range for fully automatic Namkeen packing machines? Prices vary widely depending on features and brands but can range from 1,00,000 Rs to 5,00,000 Rs.

Are there financing options available for purchasing these machines? Yes, many manufacturers offer financing plans, making it easier to invest in the right machine.

How do I maintain and care for a packing machine? Regular cleaning, scheduled maintenance checks, and following the manufacturer’s instructions are essential for longevity.

Can fully automatic machines be customized for different Namkeen types? Definitely! Most manufacturers offer customization options based on the specific type of nankeen being packed.

What are the common challenges faced when operating these machines? Common challenges include ensuring proper settings for different products, maintenance issues, and occasional mechanical failures.